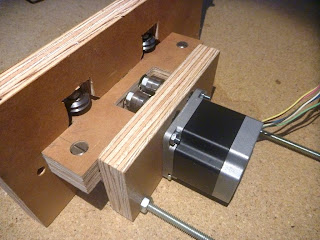

The last wood parts that I'm using from the WhiteAnt design are the stepper motor mounts for the 3 axes. The motors will also be installed at this time, since each mount must have the motor attached before assembly.

Of all the WhiteAnt literature I have found, there are no specifications given for the stepper motor except for the size: NEMA 23. I purchased from an eBay seller (3) used Vexta PK266-02A steppers with 3/4" shafts. They have 6 leads and can be wired as bipolar.

I started with the most difficult assembly: the Y-axis and then worked my way up to the Z-axis which was the easiest to assemble. The only problem I incurred was that I found that the 3/4" length of the stepper motor shaft is too short, but with slight modifications I was able to make it work.

No specifications are given for the belts and pulleys for this printer. Since my familiarity is with the metric T5 belts used on the RepRap machines, I decided to go with this, BUT with an improvement. I think the higher precision of a T2.5 system will make it better.

Of all the WhiteAnt literature I have found, there are no specifications given for the stepper motor except for the size: NEMA 23. I purchased from an eBay seller (3) used Vexta PK266-02A steppers with 3/4" shafts. They have 6 leads and can be wired as bipolar.

I started with the most difficult assembly: the Y-axis and then worked my way up to the Z-axis which was the easiest to assemble. The only problem I incurred was that I found that the 3/4" length of the stepper motor shaft is too short, but with slight modifications I was able to make it work.

|

| All motors in place and T2.5 belt in place for X-axis. |

|

| Y-axis |

|

| X-axis |

|

| Z-axis |

No specifications are given for the belts and pulleys for this printer. Since my familiarity is with the metric T5 belts used on the RepRap machines, I decided to go with this, BUT with an improvement. I think the higher precision of a T2.5 system will make it better.

|

| Top is a T5 belt and pulley and the bottom is a T2.5 |

No comments:

Post a Comment