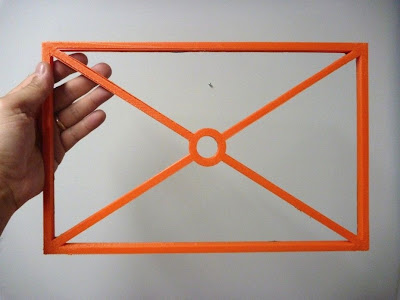

This test will use the maximum printable area of the print bed which is 360mm x 240mm. I created a model in Google SketchUp that fills an area 350mm x 220mm (13.8" x 8.7"). The walls are 10mm high and 8mm thick and the outer diameter of the circle is 40mm.

Here is the print data:

Extruder Nozzle: .5mm

Print Layer Thickness: .4mm

25 layers

Infill solidity ratio: 0.1

77,750 lines

15,670 filament length

Heat bed (center ref. point) temp. 61-65c

Ambient temp. 27.5c

Print Time: 4hr 32min

Critique:

Overall the first print run using the full bed was a success, but there are some trouble points that need to be mentioned.

1) a fine tuning of the axes calibration if precise pieces are required. The

X-axis measures 350mm as the model, but the Y-axis measures 5mm wider.

2) slight warping at the corners, but unobtrusive overall.

3) an odd separation of the perimeter walls toward the bottom right hand corner.

4) about 30mm inward from all 4 corner points the printing is rough.

Here is the print data:

Extruder Nozzle: .5mm

Print Layer Thickness: .4mm

25 layers

Infill solidity ratio: 0.1

77,750 lines

15,670 filament length

Heat bed (center ref. point) temp. 61-65c

Ambient temp. 27.5c

Print Time: 4hr 32min

Critique:

Overall the first print run using the full bed was a success, but there are some trouble points that need to be mentioned.

1) a fine tuning of the axes calibration if precise pieces are required. The

X-axis measures 350mm as the model, but the Y-axis measures 5mm wider.

2) slight warping at the corners, but unobtrusive overall.

3) an odd separation of the perimeter walls toward the bottom right hand corner.

4) about 30mm inward from all 4 corner points the printing is rough.

This comment has been removed by a blog administrator.

ReplyDeleteWow! Such an amazing and helpful post this is. I really really love it. It's so good and so awesome. I am just amazed. I hope that you continue to do your work like this in the future also cheap 3d printer

ReplyDelete